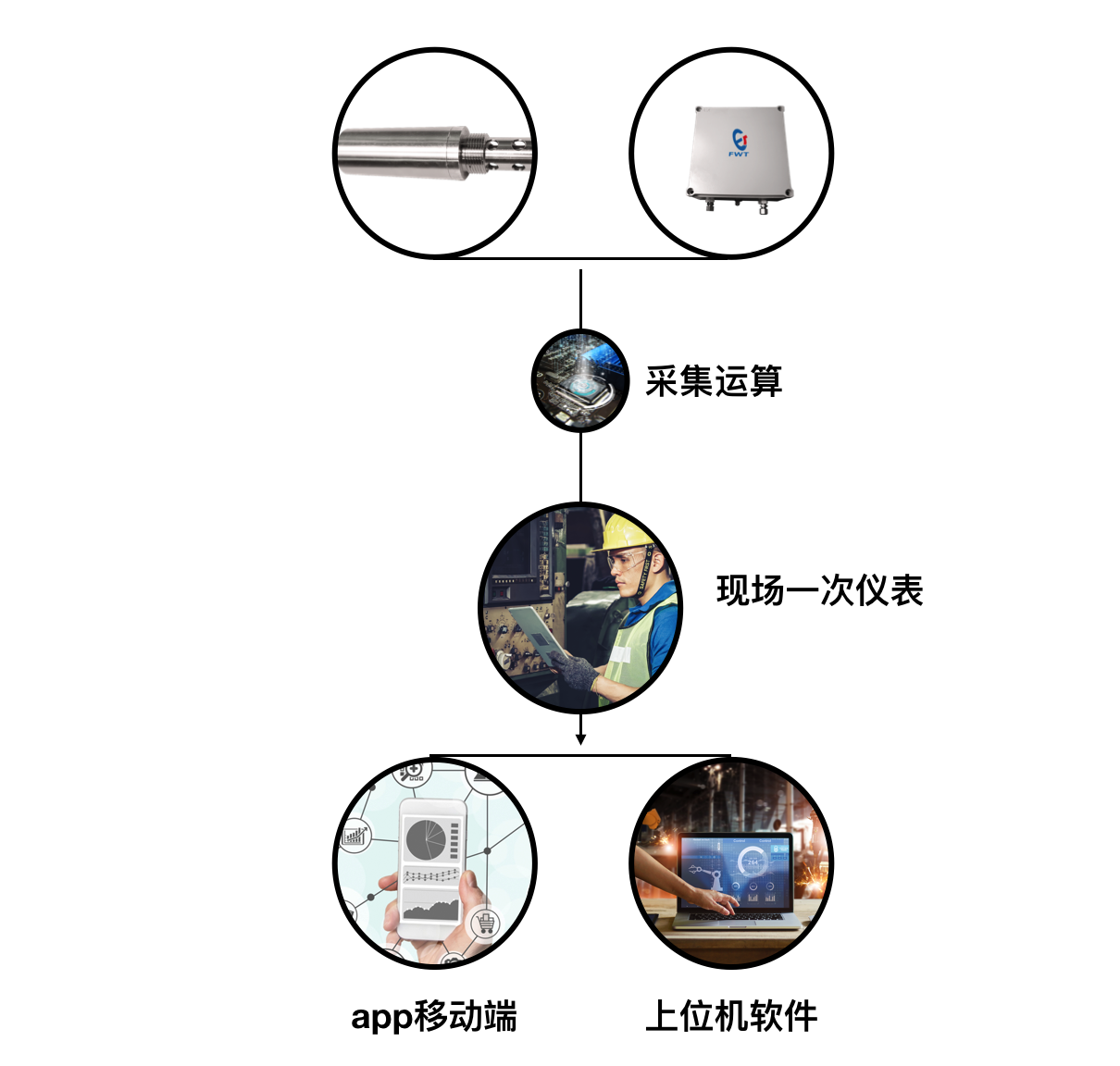

Product introduction

This product employs the design of multi-point detection and centralized display with data network. In this way, different lubrication systems of different equipment can be monitored, so that the water content and its change trend slope change overrun alarm will appear in a single monitoring unit, and the 485 communication of a single monitoring device can be transmitted to the upper computer to realize the functions of multi-point decentralized monitoring, remote and centralized control.

FWD-2000 are used in areas such as thin oil lubrication system of thick plate finishing mill, gear lubrication system of roughing mill and finishing mill in hot rolling mill, oil film bearing lubrication system of rolling mill, gear box lubrication system of five stand rolling mill in cold rolling mill, oil film bearing lubrication system of rolling mill, central lubrication station of steel pipe, C thin oil lubrication system of high-speed wire, etc.

Technical parameters

1. Water contamination (accuracy): 0% ~ 10% (0.1%), 10% ~ 30% (0.2%),

> 30% customization

2. Temperature accuracy: 0.3 ℃, Resolution: 0.01%

3. Power supply: 12VDC ~ 30VDC (typical value is 24VDC)

4. Working temperature: 0 ~ + 80 ℃; <-15 ℃ customization;

5. Ambient temperature:-40 ~ + 80 ℃

6. Working pressure: 0 ~ 1Mp (high pressure sensor: 5Mp)

7. Material: 304 stainless steel

8. Mechanical interface: M24*1. 5, flange, flow-through type;

9. Protection level: IP67

System composition